Indexer Work holding

There are a vast range of work holding capabilities for the speed indexer units. This ranges from standard face plates through to pneumatic chucks and expanding mandrels. Alpha Machine Tools would be pleased to quote for any application.

STD 125 Indexer |

Fitted-with-3-Jaw-Chuck |

Using fixture for Casting |

Fitted with 5C Collet Chuck |

As well as the methods shown here, the variation of possible workholding systems is endless. |

Manually Operated Tailstock

|

As an additional benefits to the small CNC Machining Centre user is that as the indexer is relatively small and certainly cost effective compared with ‘true’ fourth axes. More than one indexer can be mounted on a machine table to give multiple component machining capability. On a multiple set up there is still only a need for one M code function to generate an index, a compact interface unit takes care of the required input and output signals. An example of this is shown below.

A Bridgeport VMC 800/22 Vertical Machining Centre fitted with a bank of four PTG 125 Indexers

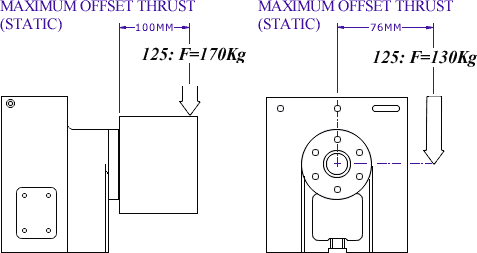

PTG 125 Indexer General Data

|

|

TYPE

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

| 125 |

198 |

225 |

125 |

100 |

155 |

15 |

170 |

95 |

40 |

6 |

|

|

STANDARD INDEX POSITIONS

|

15,30,45,60,90, DEGREES |

|

INDEDXER ROTATION

|

COUNTER CLOCKWISE

|

| AIR PRESSURE REQUIRED |

60 – 80 P.S.I.

|

|

CONCENTRICITY

|

.008MM TIR |

| ACCURACY |

+ / – 1 MIN. OF ARC

|

| ELECTRICAL REQUIREMENTS |

24V DC / 200 MA MAX

|

| MINIMUM INDEX (SPECIAL) |

5 DEGREES

|

| SPECIAL INDEX POSITIONS KITS |

AVAILABLE UPON REQUEST

|

| The PTG Index Units can be fitted to any cnc vertical machining center which has a spare ‘M’ code (M FIN). The end user is responsible for any hard wiring and software modifications that may be needed. |

Please note:

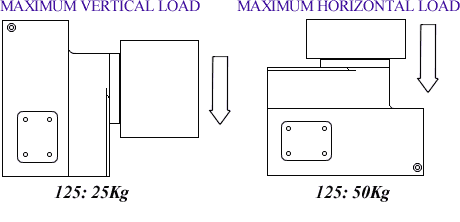

As the indexers are mechanically indexed it is preferable that all loads are evenly balanced about the centre. |